Chicken Coop Plan FAQ

Are your chicken coop plans beginner-friendly?

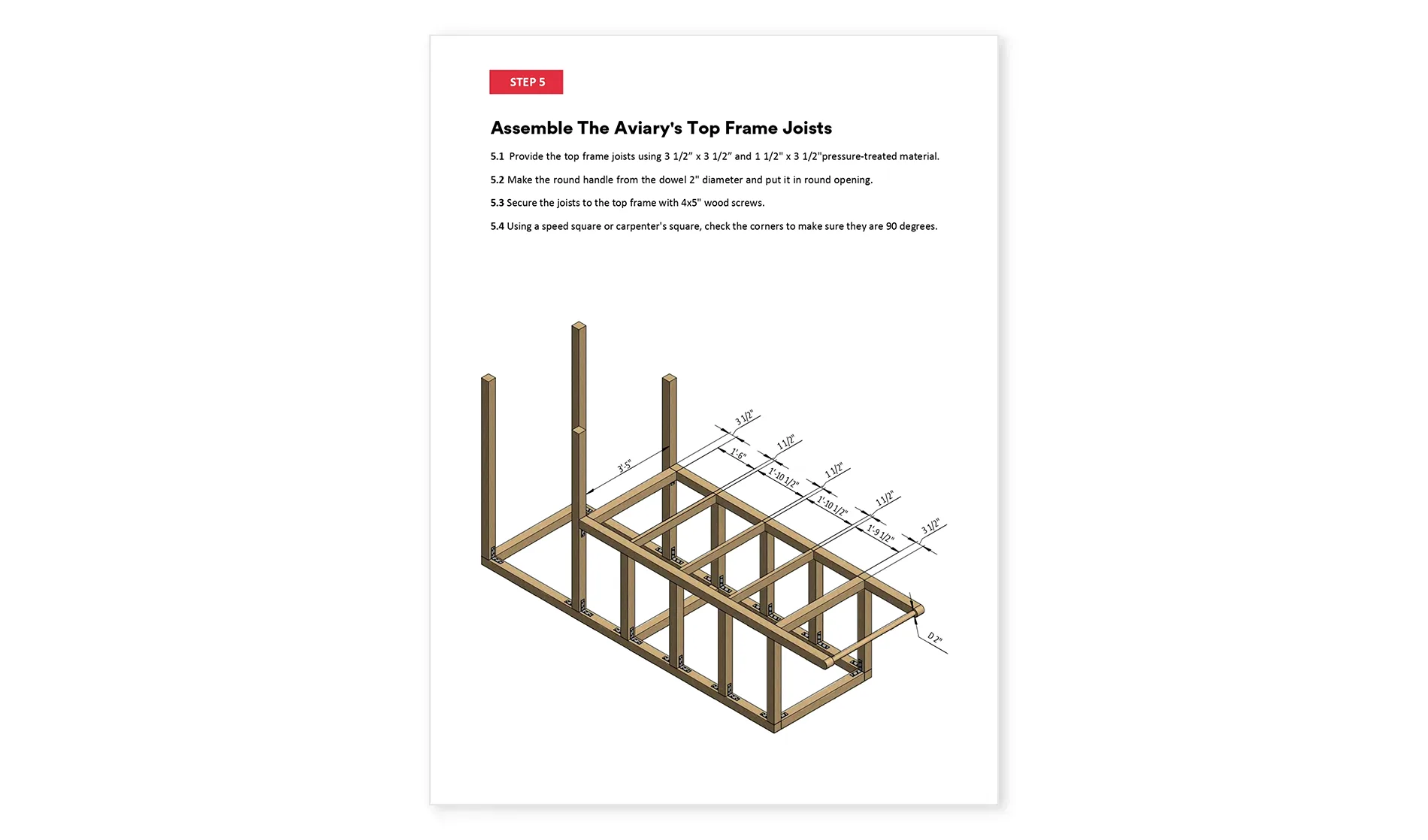

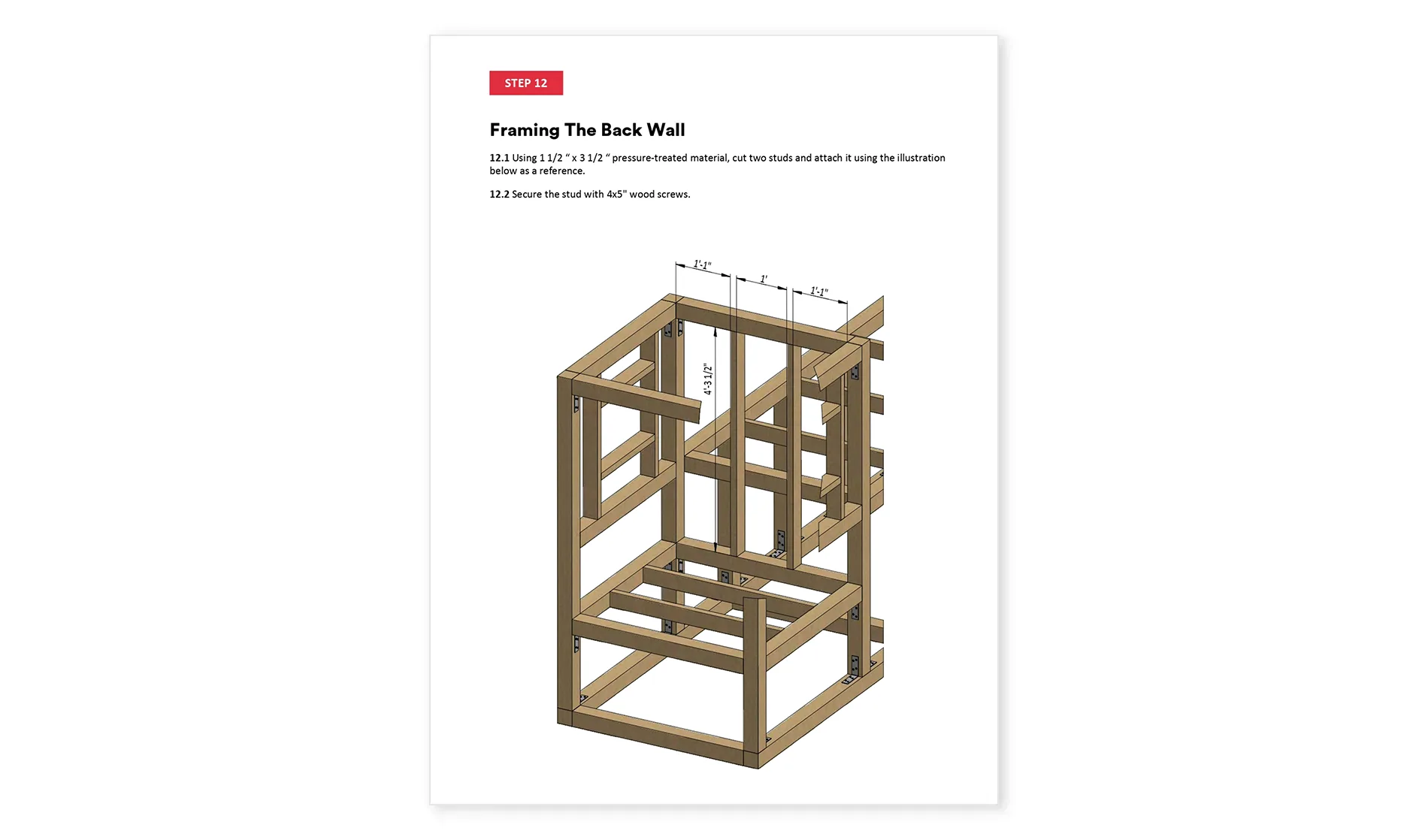

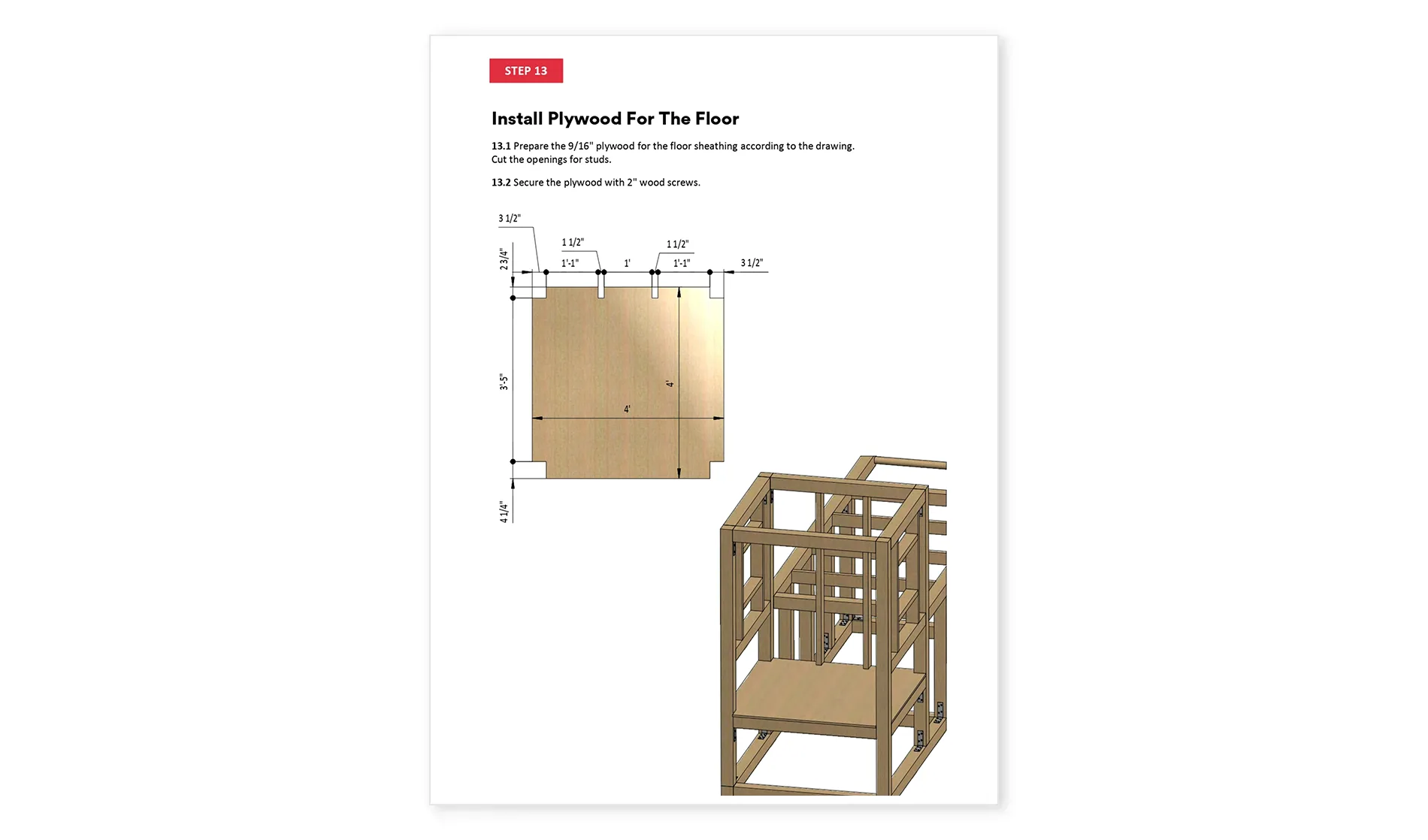

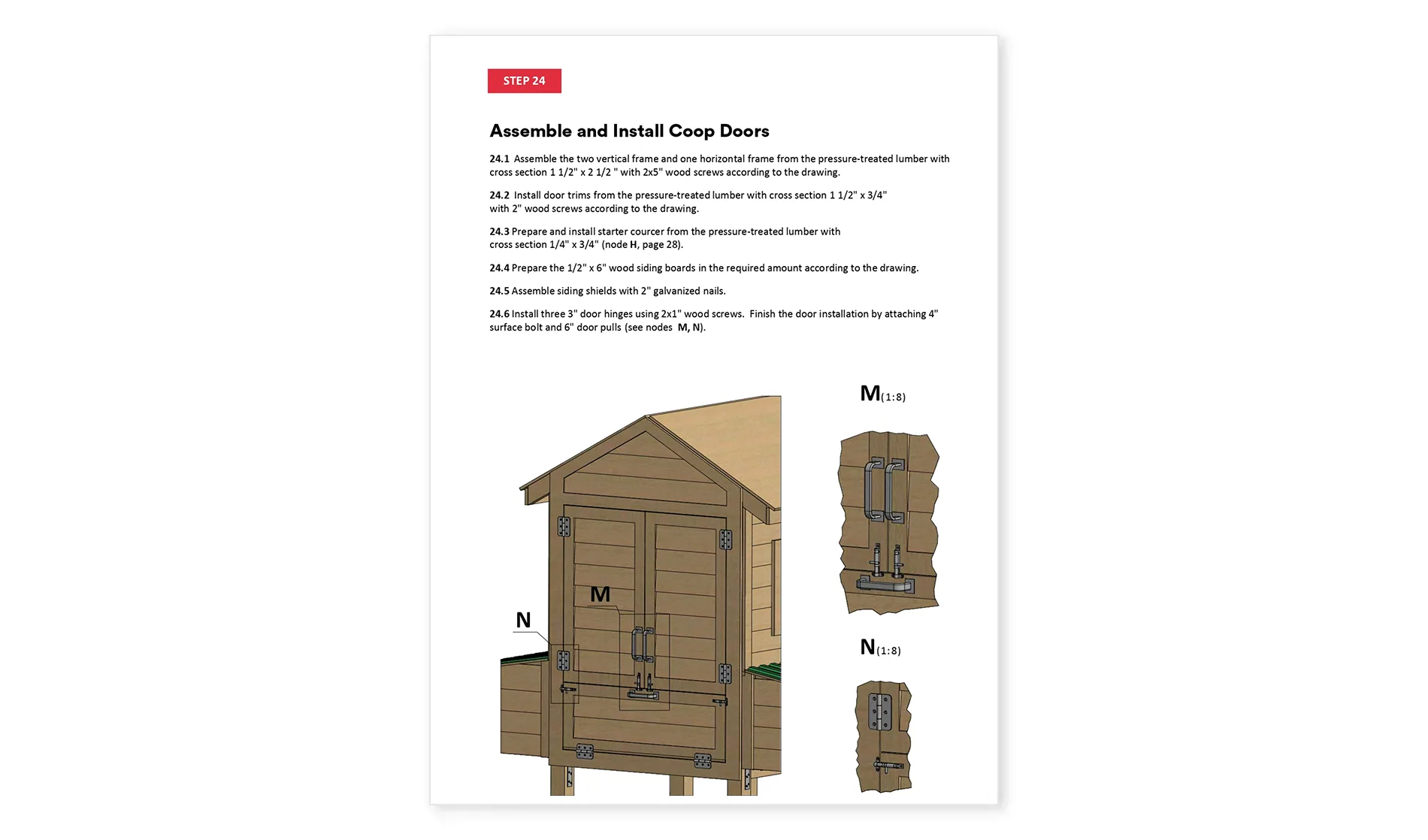

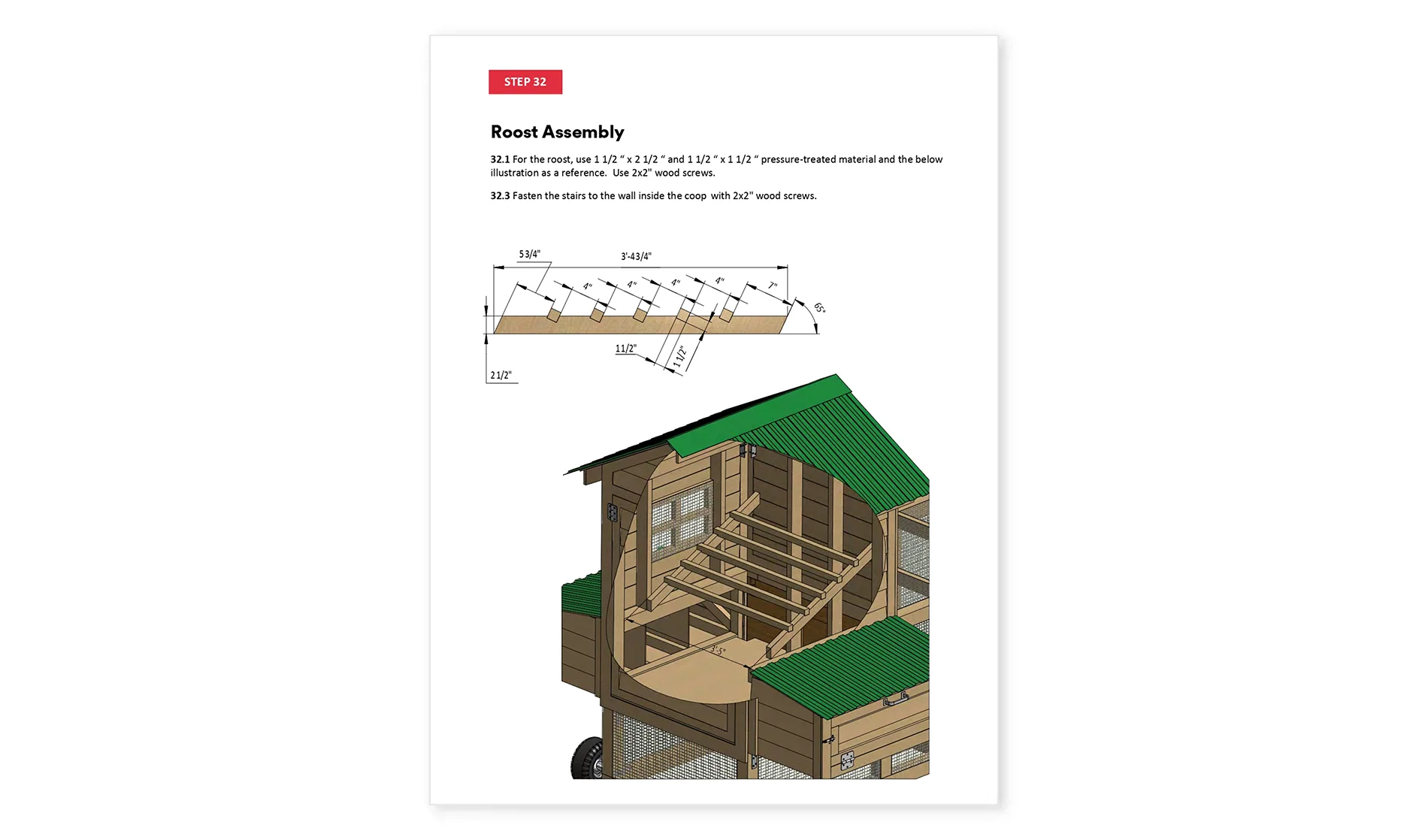

Our chicken coop plans are crafted with clarity in mind, making them suitable for a range of skill levels. While having some basic woodworking or construction knowledge can be beneficial, the plans are designed to be accessible even for beginners. Each plan comes with detailed instructions, step-by-step guides, and illustrations to ensure a smooth building process. If you’re a novice, just make sure to carefully read through the entire plan before starting and don’t hesitate to seek advice or assistance if needed.

I purchased your plans but I'm not sure how to download them, can you advise?

After completing your purchase, you should have received an email containing a download link for the chicken coop plans. If you’re still unable to locate it or have issues with the download link, please contact us directly via email. We’ll promptly assist you and, if necessary, send you the plans manually to ensure you receive what you’ve purchased.

Do you offer your chicken coop plans using metric measurements units?

Our plans are currently available exclusively in imperial units. However, a select few plans are designed with both metric and imperial units. Please refer to the product descriptions to find the one that aligns with your preferences.

How much do the materials cost to build this chicken coop?

The typical cost to construct a chicken coop is between $300 and $2,000, with the national average standing at $650. Several factors influence this price, such as:

- Coop size

- Chosen materials

- Design intricacy

- DIY versus hiring a professional

- Local labor rates

To save costs, consider building a basic coop on your own using repurposed materials. But if you desire a fancier coop or lack the expertise or time to do it yourself, hiring a contractor might be a good idea.

Can I customize the dimensions or features of this chicken coop plan?

Yes, you can modify the dimensions or features if you have the necessary experience. However, please be aware that by doing so, the material and cutting lists provided will no longer align perfectly with the instructions in the plan. This means you’ll need to adjust and calculate some of the required materials and cuts yourself. Always ensure that any changes maintain the structural integrity and safety of the coop for your chickens.

Are your chicken coops well-insulated for cold climates?

Our chicken coop plans are designed to provide basic protection against the elements. The majority of the coop plans include additional steps for insulation. However, if you’re in a particularly cold climate, you might want to enhance insulation further to ensure the comfort and safety of your chickens. Always prioritize the health and well-being of your chickens when making modifications.

How many chickens can your different-sized chicken coops comfortably accommodate?

The capacity of a chicken coop, in terms of the number of chickens it can house comfortably, is influenced by its size. Here’s a basic breakdown:

- Small Coop (4-6 square feet): Suitable for 2-3 chickens.

- Medium Coop (6-10 square feet): Designed for 4-6 chickens.

- Large Coop (10-15 square feet): Can accommodate 6-8 chickens.

- Extra Large Coop (15+ square feet): Fits 8-10+ chickens.

It’s crucial to understand that these figures serve as general guidelines. The ideal number of chickens for a coop will also be affected by factors like the chicken breed, local climate, and coop design.

For instance, bigger chicken breeds like Cochins and Brahmas demand more room compared to smaller breeds like Leghorns and bantams. If you’re in a warmer region, giving your chickens extra space can assist in keeping them cool. Furthermore, the coop’s layout and design efficiency play a role; a poorly planned coop might house fewer chickens than one that’s well-organized and designed.

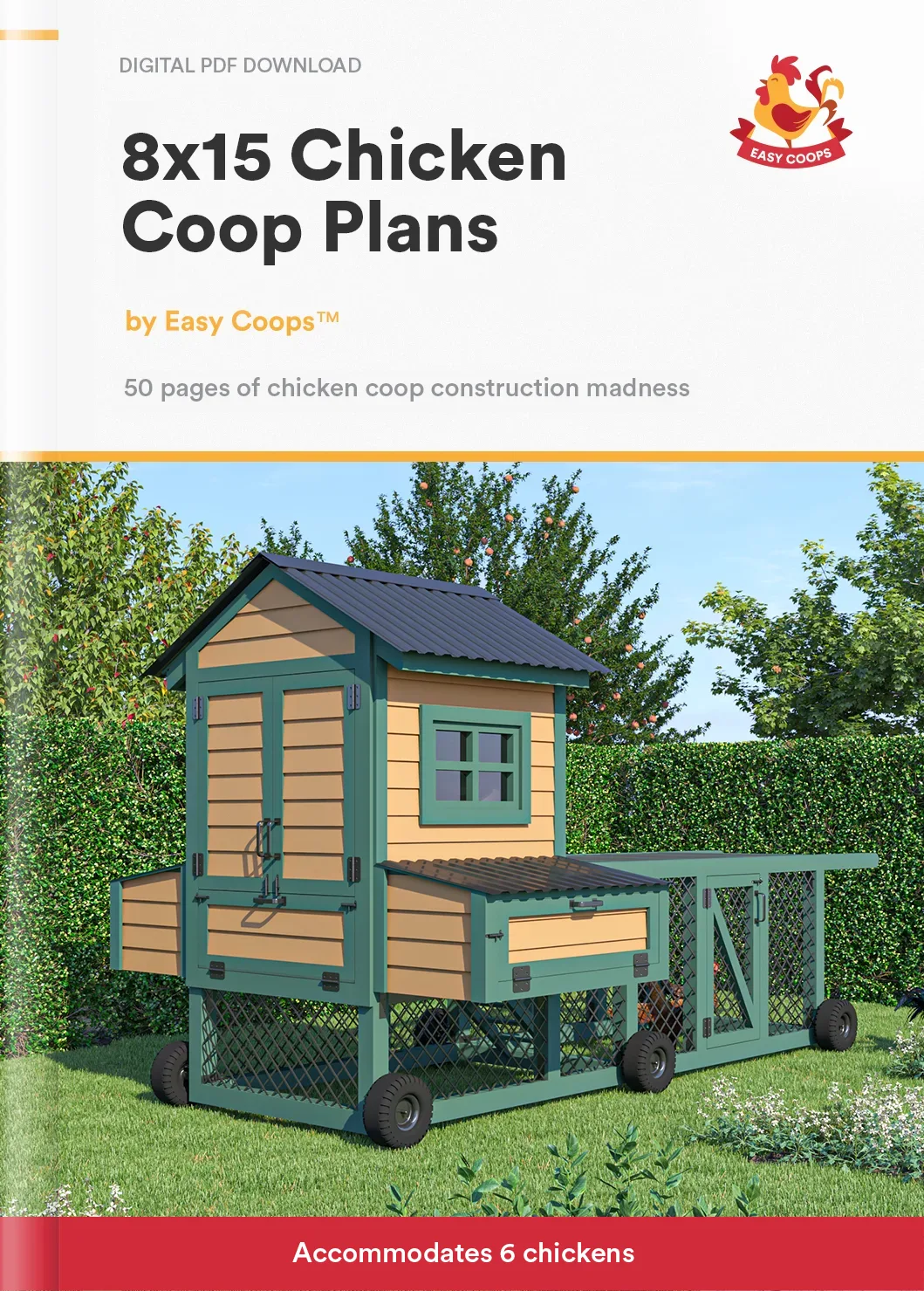

Do your chicken coop runs need to be permanently installed or can the coops be moved?

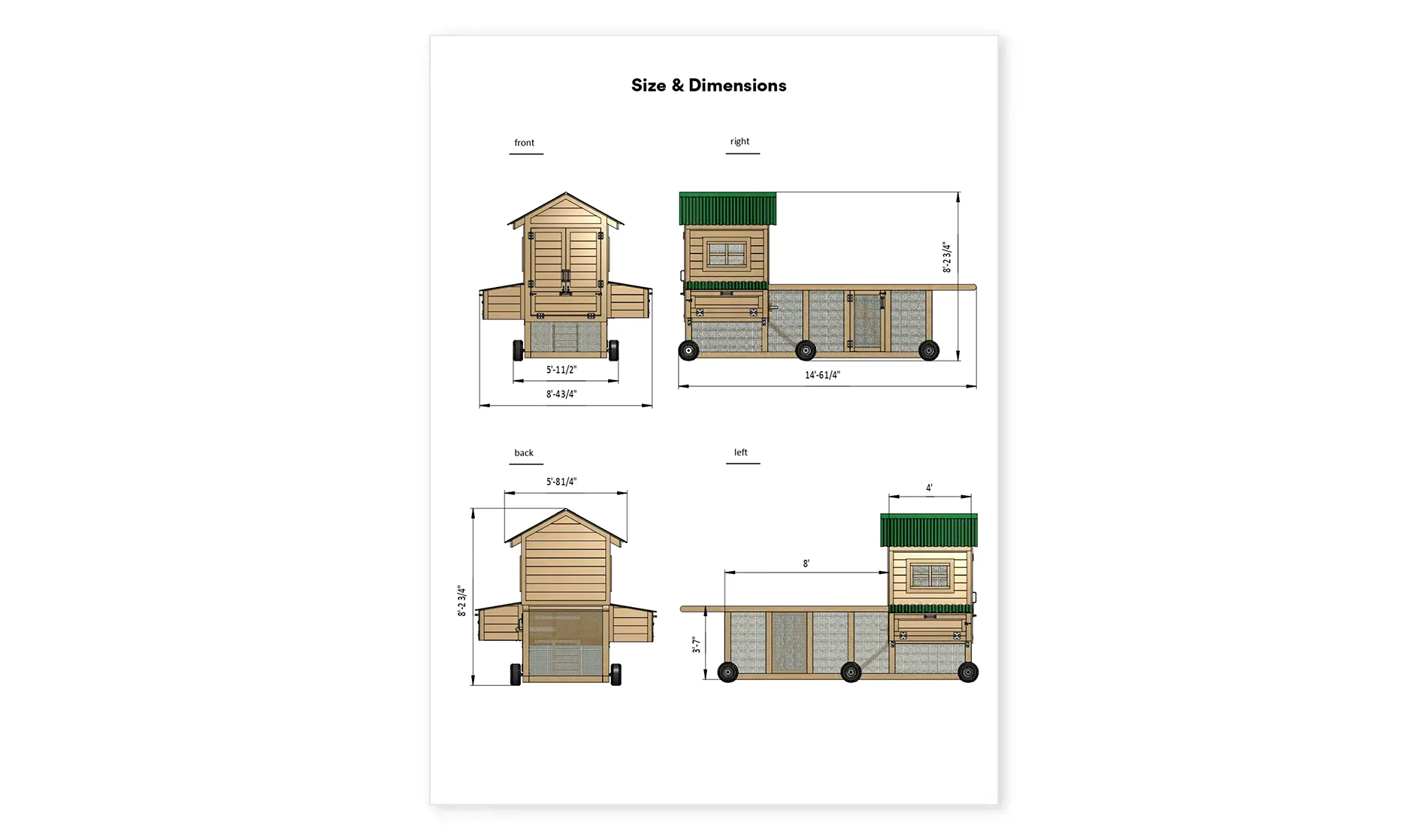

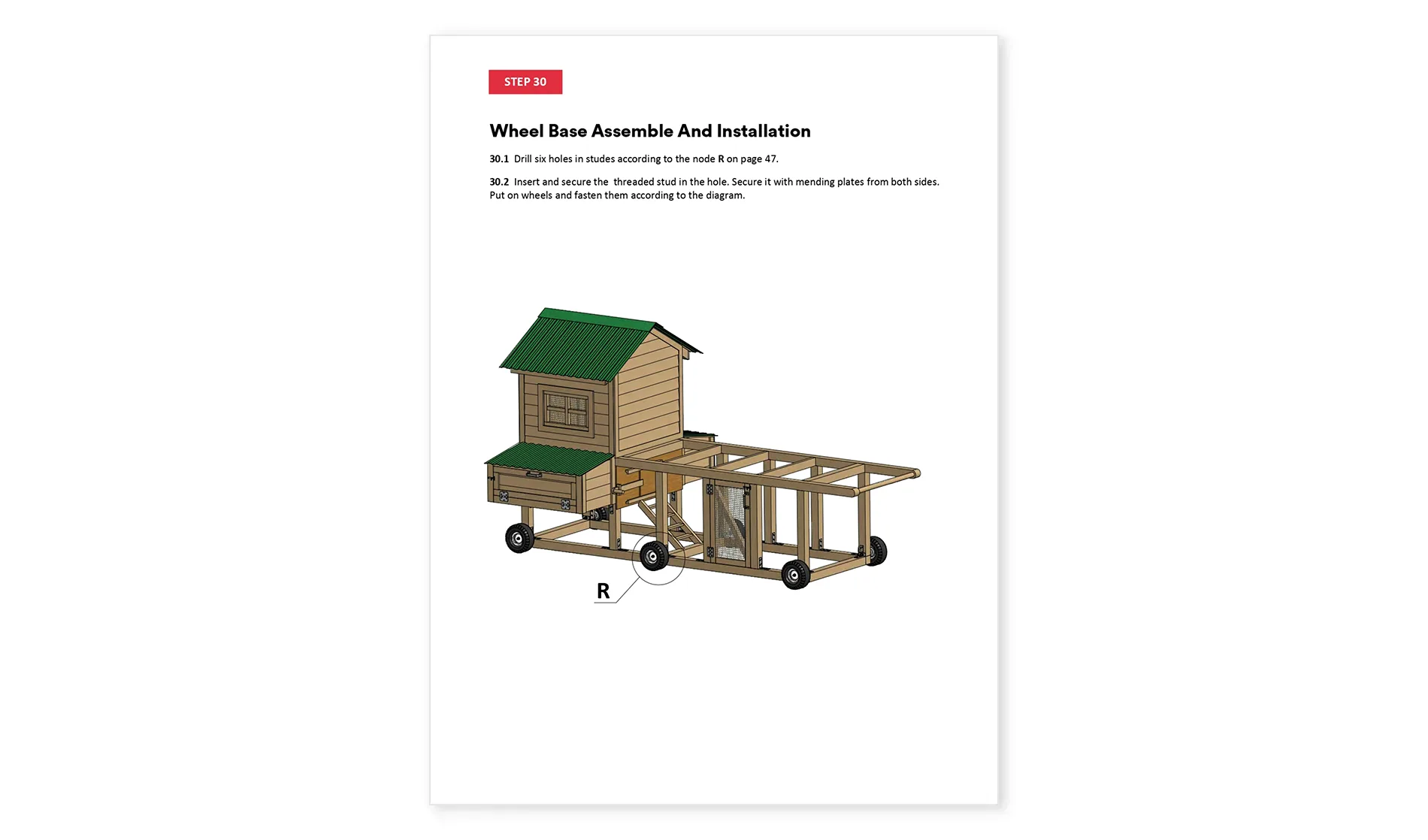

While we recommend permanent installation for optimal stability, you have the flexibility to skip the foundation and securement steps if you do not require additional protection and wish to move the coop. Additionally, we are offering portable chicken coop designs.

I'm unsure about some coop plan steps. Can you clarify a specific area?

Please don’t hesitate to reach out with any questions or uncertainties you may have about specific construction steps. Our 24/7 email support will assist you and provide any guidance you need.